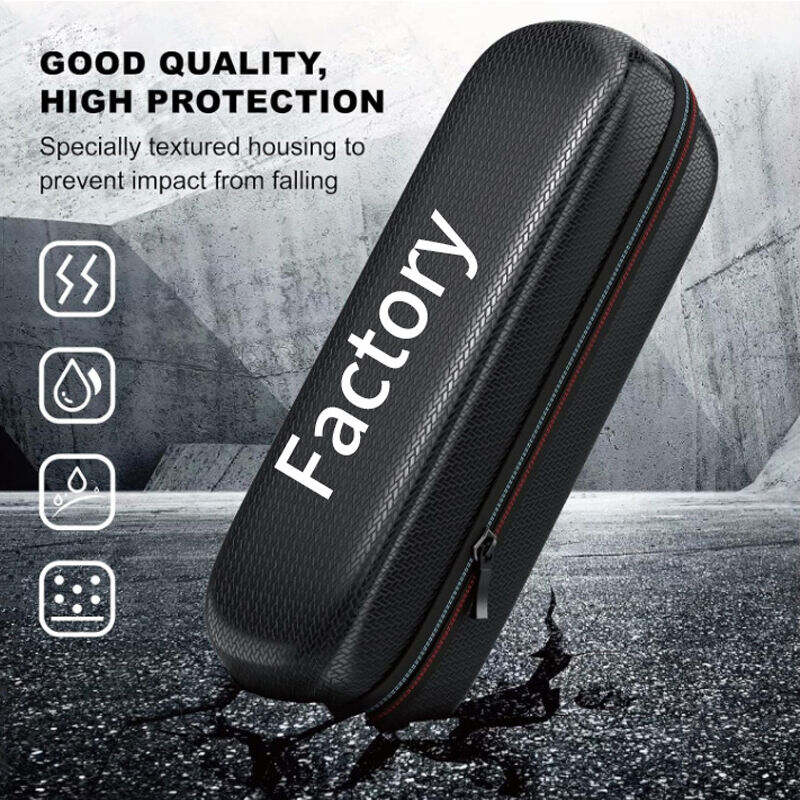

Digital devices have become integral to our daily lives, from smartphones and tablets to portable gaming consoles and electronic accessories. However, these valuable gadgets are vulnerable to damage from drops, impacts, moisture, and dust. An EVA Case offers superior protection through its unique ethylene-vinyl acetate foam construction, providing shock absorption and weather resistance that traditional storage solutions cannot match. This innovative protective solution has gained popularity among professionals and consumers who need reliable device protection without compromising portability.

Understanding EVA Material Properties

Chemical Composition and Structure

EVA material consists of ethylene and vinyl acetate copolymers that create a closed-cell foam structure with exceptional protective qualities. This molecular arrangement provides excellent shock absorption capabilities while maintaining lightweight characteristics. The closed-cell design prevents water absorption and creates a barrier against environmental contaminants. Unlike traditional materials such as cardboard or basic plastics, EVA maintains its protective properties across a wide temperature range, making it ideal for diverse operating conditions.

The density of EVA foam can be customized during manufacturing to achieve specific protection levels for different device types. Higher density variations offer increased impact resistance for heavier electronics, while lower density options provide adequate protection for lightweight accessories. This versatility allows manufacturers to create specialized EVA Case designs tailored to specific device categories and user requirements.

Durability and Longevity Characteristics

EVA material demonstrates remarkable durability under repeated stress and compression cycles. Laboratory testing shows that quality EVA foam retains its shock-absorbing properties even after thousands of compression cycles, ensuring long-term protection reliability. The material resists cracking, tearing, and permanent deformation that commonly affects other protective materials over time. This durability translates to extended product lifecycles and consistent protection performance.

Environmental factors such as UV exposure, temperature fluctuations, and humidity variations have minimal impact on EVA material integrity. The chemical stability of ethylene-vinyl acetate copolymers prevents degradation from common environmental stressors. This resistance ensures that an EVA Case maintains its protective capabilities throughout extended use periods, providing reliable device protection across various storage and transportation scenarios.

Protection Mechanisms Against Physical Damage

Impact Absorption Technology

The cellular structure of EVA foam creates thousands of tiny air pockets that compress upon impact, dissipating kinetic energy before it reaches protected devices. This energy distribution mechanism significantly reduces the force transmitted to electronic components during drops or collisions. Independent testing demonstrates that EVA cases can reduce impact forces by up to 90% compared to unprotected storage methods. The material's elastic properties allow it to return to its original shape after compression, maintaining consistent protection performance.

Multiple layers of EVA foam can be incorporated into case designs to enhance protection levels for particularly vulnerable devices. Strategic placement of varying density foam sections provides targeted protection for device corners, screens, and other critical areas. This engineered approach ensures optimal force distribution while maintaining reasonable case dimensions and weight. The result is comprehensive protection that addresses the specific vulnerability patterns of different electronic device categories.

Vibration and Shock Isolation

Beyond impact protection, EVA material provides excellent vibration dampening properties that protect sensitive electronic components from cumulative damage. Continuous vibration exposure during transportation can cause micro-damage to circuit boards, connectors, and other precision components. The viscoelastic properties of EVA foam absorb and dissipate vibrational energy across a broad frequency range, preventing resonance conditions that could amplify damaging forces.

Professional applications often require devices to withstand significant shock loads during transportation or field use. Military and industrial specifications for electronic equipment protection frequently reference EVA-based solutions due to their proven shock isolation capabilities. The material's ability to maintain protection performance across temperature extremes makes it suitable for demanding operational environments where device reliability is critical.

Environmental Protection Features

Moisture and Water Resistance

The closed-cell structure of EVA material creates a natural barrier against moisture infiltration, protecting electronic devices from humidity and water damage. Unlike open-cell foams that can absorb and retain moisture, EVA maintains its protective properties even in high-humidity environments. This moisture resistance is particularly valuable for devices used in outdoor applications or stored in varying environmental conditions. The material's hydrophobic properties prevent water absorption that could lead to mold growth or material degradation.

When combined with proper sealing mechanisms, an EVA Case can provide near-waterproof protection for sensitive electronics. Zipper systems with water-resistant treatments and gasket seals create comprehensive moisture barriers. This protection level is essential for devices used in marine environments, construction sites, or other locations where water exposure is a constant concern. The combination of EVA material properties and engineered sealing solutions delivers professional-grade environmental protection.

Dust and Particle Exclusion

Fine particles and dust can infiltrate electronic devices through ventilation openings, causing overheating and component failures over time. EVA material's smooth surface and closed-cell structure prevent particle accumulation and make cleaning simple and effective. The material does not generate static charges that could attract airborne particles, maintaining a clean protective environment for stored devices. This anti-static property also prevents electrostatic discharge events that could damage sensitive electronic components.

Industrial environments often contain abrasive particles that can damage device surfaces and infiltrate internal components. EVA cases provide a protective barrier that isolates devices from these contaminants while maintaining accessibility for normal use. The material's chemical resistance ensures that exposure to common industrial chemicals and solvents does not compromise protective performance. This comprehensive contamination protection extends device lifecycles and maintains operational reliability in challenging environments.

Design Optimization for Device Protection

Custom Fit and Internal Organization

Effective device protection requires precise fit and internal organization that prevents movement during transportation. EVA material can be precisely cut and shaped to create custom compartments that cradle devices and accessories without excessive compression. Computer-controlled cutting systems enable manufacturers to create complex internal geometries that accommodate device-specific features such as cameras, ports, and control buttons. This precision fitting eliminates movement-related damage while maintaining easy device access.

Internal organization systems within EVA Case designs can include removable dividers, elastic retention straps, and dedicated accessory pockets. These organizational features prevent device-to-device contact that could cause scratches or impact damage. Soft-touch EVA surfaces provide additional scratch protection while maintaining the material's shock-absorption properties. The combination of custom fitting and organizational features creates comprehensive protection systems tailored to specific device families and user requirements.

Ergonomic and Functional Considerations

Modern EVA case designs balance protection requirements with user convenience and portability. Ergonomic handle designs distribute carrying loads evenly, reducing user fatigue during extended transportation periods. Strategic placement of zippers and openings provides device access without compromising protection integrity. These design considerations ensure that enhanced protection does not create barriers to normal device use and maintenance procedures.

Modular case systems allow users to configure protection levels based on specific transportation and storage requirements. Removable EVA inserts can be swapped to accommodate different device configurations or protection needs. This flexibility extends product utility while maintaining the fundamental protective advantages of EVA material construction. Professional users particularly value this adaptability when managing diverse device inventories with varying protection requirements.

Comparison with Alternative Protection Methods

Traditional Hard Cases versus EVA Solutions

Hard plastic and metal cases provide excellent puncture resistance but often lack the shock absorption properties necessary for comprehensive device protection. While these materials resist external impacts, they can transmit significant forces to internal contents during drops or collisions. EVA material combines structural protection with energy absorption, providing more comprehensive damage prevention. The weight advantage of EVA solutions also improves portability without sacrificing protection performance.

Temperature sensitivity affects many traditional case materials, causing brittleness in cold conditions and softening in extreme heat. EVA material maintains consistent protective properties across operational temperature ranges commonly encountered in professional and consumer applications. This temperature stability ensures reliable protection regardless of storage or transportation conditions. The material's flexibility also prevents stress concentration that could lead to catastrophic failure in rigid case materials.

Soft Pouches and Basic Storage Solutions

Basic fabric pouches and soft storage solutions offer minimal protection against physical damage and environmental hazards. While these solutions provide scratch protection and basic organization, they cannot prevent damage from drops, impacts, or crushing forces. EVA cases deliver significantly enhanced protection while maintaining comparable portability and user convenience. The structured design of EVA solutions also provides better internal organization and device accessibility.

Cost considerations often drive selection of basic storage solutions, but the superior protection offered by EVA cases typically justifies the investment through extended device lifecycles and reduced repair costs. Insurance replacement costs for damaged electronics often exceed the price of quality protective cases by significant margins. Professional users recognize this value proposition and increasingly specify EVA-based protection solutions for valuable electronic equipment inventories.

Industry Applications and Use Cases

Professional and Commercial Applications

Healthcare professionals rely on portable diagnostic equipment and electronic devices that require reliable protection during patient visits and equipment transportation. EVA cases provide the shock absorption and contamination protection necessary for medical electronics while maintaining the sterile storage conditions required in healthcare environments. The material's resistance to common disinfectants ensures that protection performance is not compromised by cleaning protocols.

Field service technicians and engineers depend on electronic testing equipment, tablets, and communication devices that must function reliably despite challenging operational conditions. EVA case protection prevents damage from drops, vibration, and environmental exposure that commonly occurs during field work. The lightweight construction of EVA solutions reduces equipment carrying loads while providing professional-grade protection. This combination of protection and portability directly impacts technician productivity and equipment reliability.

Consumer and Personal Applications

Travel and outdoor recreation activities expose personal electronics to conditions that exceed normal usage parameters. EVA cases provide protection against impacts, moisture, and temperature variations commonly encountered during travel and outdoor activities. The material's resistance to UV degradation ensures long-term protection performance for devices used in sunny environments. Compact case designs accommodate airline carry-on restrictions while providing comprehensive device protection.

Gaming enthusiasts and mobile professionals often transport expensive portable gaming systems, tablets, and accessories that represent significant investments. EVA case protection prevents damage during transportation while providing organized storage for multiple devices and accessories. The shock-absorption properties are particularly important for devices with moving parts such as hard drives and optical drives that are susceptible to impact damage. Consumer adoption of EVA protection solutions continues to grow as device values increase and replacement costs escalate.

FAQ

How does EVA material compare to foam rubber for device protection

EVA material offers superior durability and maintains its protective properties longer than traditional foam rubber. While foam rubber can compress permanently and lose shock-absorption capabilities over time, EVA material recovers its shape and maintains consistent protection performance through thousands of compression cycles. EVA also provides better resistance to environmental factors such as ozone, UV exposure, and temperature variations that cause foam rubber to degrade and become brittle.

Can EVA cases protect devices from electromagnetic interference

Standard EVA material does not provide electromagnetic shielding properties, but specialized EVA cases can incorporate conductive fabrics or mesh layers to create Faraday cage effects. These hybrid designs combine the shock absorption benefits of EVA foam with EMI protection capabilities. For applications requiring electromagnetic protection, users should specify cases with integrated shielding features rather than relying solely on EVA material properties.

What temperature ranges can EVA cases withstand without losing protective properties

Quality EVA materials maintain their protective characteristics across temperature ranges from approximately -40°F to 180°F (-40°C to 82°C). This temperature stability makes EVA cases suitable for use in automotive environments, outdoor applications, and varying storage conditions. The material does not become brittle in cold conditions or excessively soft in heat, ensuring consistent protection performance across normal operational temperature ranges.

How should EVA cases be cleaned and maintained for optimal performance

EVA cases require minimal maintenance and can be cleaned with mild soap solutions and water. The non-absorbent surface prevents contamination from penetrating the material, making cleaning simple and effective. Avoid harsh chemicals, petroleum-based solvents, and abrasive cleaning methods that could damage the surface texture. Regular inspection of zippers, seals, and structural components ensures continued protection performance and identifies any replacement needs before protective capabilities are compromised.